Standard Functions

Many standard functions are already integrated in the HMI framework, such as recipe management or user management.

The following standard functions can be flexibly integrated into a Windows HMI application and thus cover your basic requirements.

Operators of WIT-HMIs rate the user interface as "intuitive and clear"

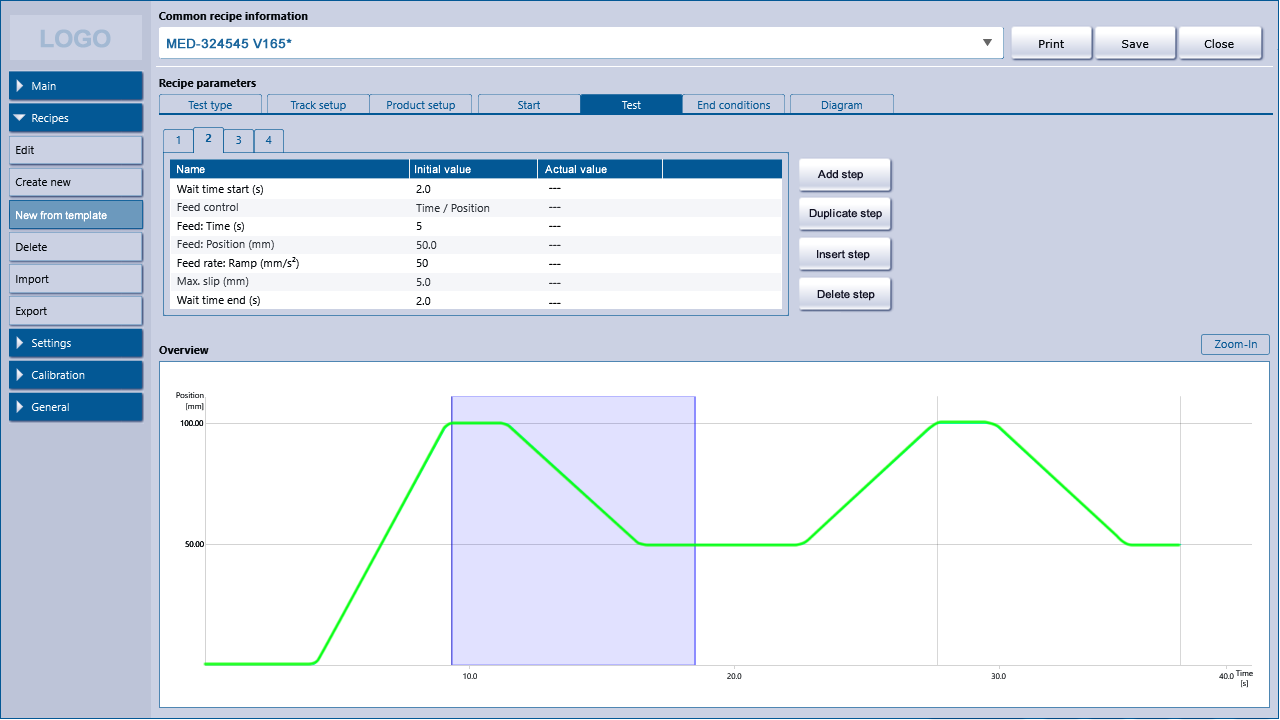

The process parameters are clearly structured in the recipe and then visualized accordingly on the touch screen or in the printout.

The recipe management contains features such as:

- Version control:

A new version is created each time the recipe is edited. Depending on the administrator setting, older versions can also be loaded by the operator. - Support for multiple recipe storages:

Recipes are grouped or sorted in recipe storages. For example, a storage for production recipes and a storage for engineering recipes can be created. Storage access can be configured in such a way that, for example, production employees can only load recipes that have been released for production. - Define parameter limits in engineering:

Process engineers can mark certain parameters as "adjustable" for production and define the minimum/maximum range for inputs in production. - Offline mode:

Recipes can also be created or edited offline with the HMI application, ie without a connected machine. - File system:

Recipes are saved in a file folder, signed if required. Recipes can also be stored centrally on a file server and can be easily exported and imported.

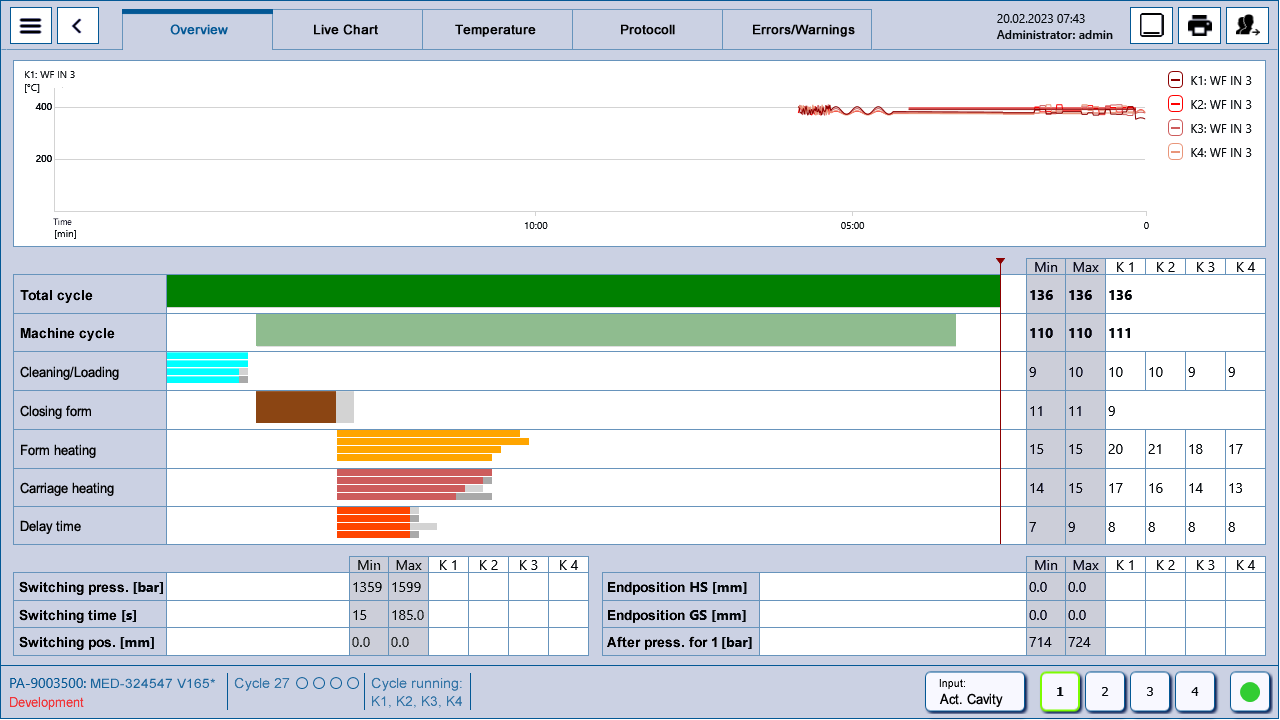

The process documentation includes:

- Process/recipe parameters actually used during the process run (set points)

- Depending on the application, important process results of the process

- Important actual values are periodically recorded in the time diagram

- If required, a process video or just a process photo at the start and end of the process

The data are stored in XML files in a folder designated for the process run and the files are used for output generation for the printer, Excel file generation and PDF/XPS file generation.

The possible user roles are defined individually for each HMI application. Users must log in to operate. Exception: A «standard user» may be defined for the automatic login. The standard user usually has only minimal rights. If desired, the user administration can be coupled with the Active Directory of Windows.

The order management allows all production processes to be assigned to a charge/batch. Processes can also be numbered individually, e.g. by scanning the product ID. In the process history view, all processes of an order can be easily viewed and then process data can be generated in an Excel file.

Camera Preview:

One or more cameras can be embedded in the HMI application. Both the digital zoom and preview properties such as brightness and contrast can be changed in the HMI settings.

Process Video:

Video recording during a process run is also available as a standard function. The video can be used for better traceability or for training purposes.

Important actions such as the occurrence of alarms and warnings, starting or ending a process or logging in or out of a user are logged and persisted.

The WIT-HMI framework is well prepared if you offer your FDA- and GMP-compliant machine on the international market. Multiple languages can be easily integrated. A unit system is also consistently integrated, so that e.g. a simple switch from °C to Fahrenheit or from psi to bar is possible.

The framework supports the integration of proprietary protocols. Various communication adapters for Siemens, Beckhoff or Allen Bradley controllers, for example, are already available. Protocol adapters have also already been implemented for the OPC UA or Modbus protocols.